Your HVAC/R units are one of the most valuable investments and important pieces of equipment on your rooftop. Appropriate attention and upkeep are essential. With routine maintenance, you can ensure your units’ optimal efficiency, take advantage of energy cost savings, and avoid costly emergency repairs. From changing filters to testing specific electrical components, discover what makes up a best-in-class HVAC/R tune-up.

What’s Included in Proper HVAC/R Maintenance?

Changing filters

Your HVAC/R system filters increase air quality by removing dust, pollen, and other small particles, preventing them from being recirculated. Filters also protect against larger particles that could damage your HVAC/R system. Over time, a neglected filter will let particles pass through and therefore accumulate inside your HVAC/R units which can affect your evaporator coil. While this can increase your energy consumption, it can also lead to catastrophic damage like a fire. Ensuring your filters are changed regularly is one of the easiest ways to prevent the breakdown of your HVAC/R units.

Maintaining the blower motor

Within your HVAC/R units, the blower motor is used to circulate air within your building. Poorly maintained blowers can accumulate dirt inside and around the blower housing. This may cause the blower motor to overheat and can catch fire and ignite nearby components. During proper maintenance, an HVAC/R technician will wipe down the blower housing and take amperage readings to confirm the motor isn't currently at risk for overheating.

Testing the electrical components

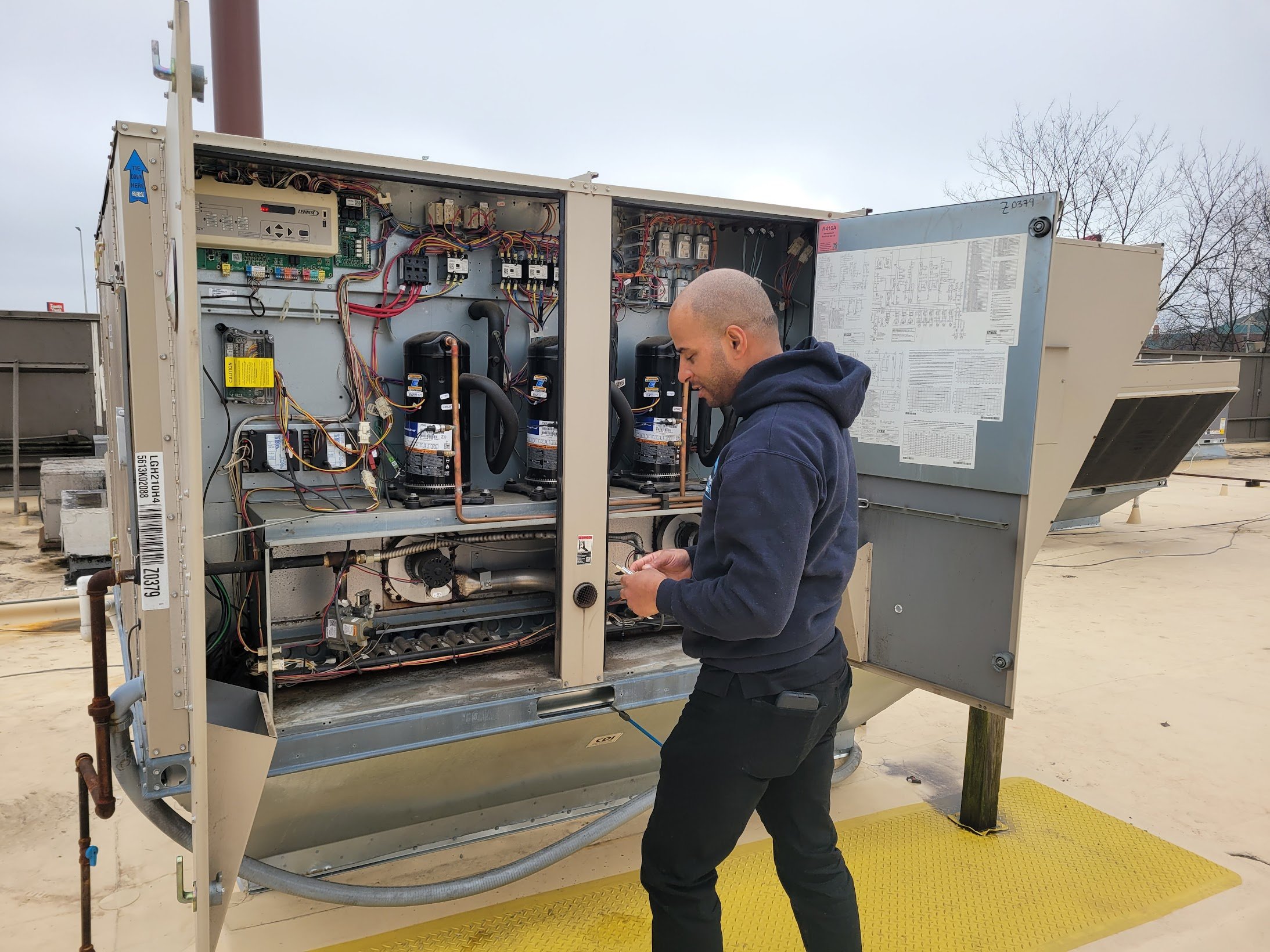

HVAC/R equipment is filled with electrical components that need to be tested and visually inspected. A trained HVAC/R technician will address loose connections and inspect components for signs of failure such as fraying, pitting, and corrosion. This is key to preventing an abrupt disruption to the future function of your HVAC/R units.

Inspecting the heat exchanger

The heat exchanger is a vital component of your heating system that is constantly expanding and contracting. Due to its continuous use, this component may crack creating safety concerns. A fractured heat exchanger will allow carbon monoxide into your business. A larger crack has the potential to start a fire due to the backdraft created when the blower motor introduces air to a sealed component. A combustion analysis and visual inspection will be performed by an HVAC/R technical. Safety switches, such as high limit and rollout switches, should never be bypassed as temporary repairs. Those guardrails are designed to reduce the chance of fire and or carbon monoxide poisoning by monitoring and shutting off the system when unsafe situations arise.

Testing for gas leaks

During installation and any gas-related repairs, your HVAC/R system should be checked for gas-related leaks. Testing should be performed by a powered gas leak detector for bubbles. Failure to follow these steps by an HVAC/R contractor can lead to both fires and bodily harm, including carbon monoxide poisoning.

Your HVAC/R system is a significant investment and should be protected. Well-documented, routine inspections from a licensed HVAC/R professional are key to preventing future operational risks and reducing your building-related costs.

We’re now offering full-service HVAC/R maintenance and repairs. AirCare is our fixed-price service program of scheduled maintenance of heating, ventilation, and cooling units to ensure optimal performance and maximal efficiency.

Written by

Josh Agosto

HVAC/R Technician